![]()

Features of NSS Models

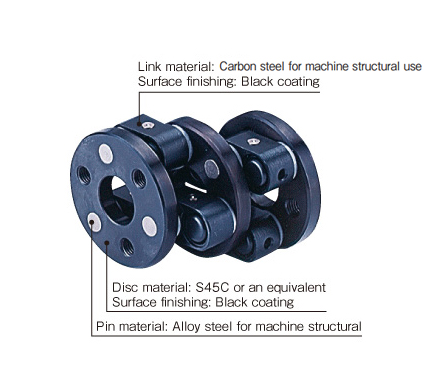

These are couplings with different shaft centers that use the crank motion of a link. Power input at one end disc is transmitted via a link and center disc to another end disc.The amount of eccentricity is determined by the length of the link. Power can be transmitted smoothly when shaft centers are different. And since power is transmitted by the crank motion of the link, translation of shaft centers during rotation is possible. The standard NSS model has 3 x 2 links, while quasi-standard NSS models increase the number of links and the rated torque.

Translation of shafts is possible

Since the crank motion of the link is used, the drive and driven shafts can be translated freely within the displacement range even when stopped or rotating under load.

Space saving

Couplings can be shortened in the axial direction and a larger amount of displacement achieved compared to the older combination of universal joint and spline.

Related Product

- Max. rated torque 220 N・m

- Bore ranges 3 mm to 35 mm

- Operating temperature -30℃ to 100℃

- Max. rated torque 8000 N・m

- Standard bore-drilling range 22 mm to 115 mm

- Backlash Zero

- Max. rated torque 25 N・m

- Bore ranges 6 mm to 22 mm

- Operating temperature -30℃ to 100℃

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어