Quality Improvement Activities

- Since its foundation in 1939, Miki Pulley has been leading the field of power transmission and control equipment as the pioneer of the field. We believe that we were able to be at the forefront for a long time because we have continued to challenge new things such as advanced technologies that are ahead of the times and reforming of production.

And maintaining high quality is one reason we have gained the complete trust of customers. One of our goals is to become a company that places high value on the quality of all things, including the quality of products, the quality of operations, the quality of employees, and the quality of the workplace environment. We have proactively carried out various quality improvement activities.

- There is one thing that we always keep in mind when we make products. That is to make sure that each of the workers understands the products of our customers. Before making products, we learn which part of the product of the customer is to be produced, where the product is used, and how it contributes to society. When you know the customer, you will have a stronger sense of responsibility, and when you have a stronger sense of responsibility, the quality will rise. Such a virtuous cycle is created. To improve quality, the attitude of workers must first be changed. We believe that this is very important.

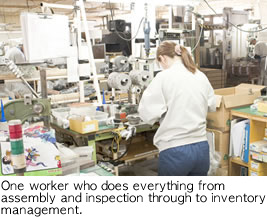

- We employ a food stall production system to make products. The production line of each product is like a food stall with an owner (worker). A large advantage of the food stall production system is that it changes the attitude of the worker. The division of labor system assigns each of the workers a special assignment such as scheduling, preparation of parts, assembly, and packing. The food stall production system, on the other hand, allows one worker to do everything from parts management through to delivery date management, so he or she has a stronger sense of responsibility. Furthermore, workers are able to get to know their customers clearly so their attitude to the work will change from passive to active and the motivation will increase. Several years have passed since we changed the division of labor system to the food stall production system, and defects have decreased dramatically and quality has improved.

- We make assembly machines and inspection equipment in-house so more than a half of all the machinery and equipment were made in-house. We identify workplaces where mistakes such as confusion regarding the number of screws and mounting in the reverse direction are likely to take place or actually took place, or where the work load on workers can be reduced, and make and use special jigs in such workplaces to prevent defects. Furthermore, we make inspection equipment to suit each product in-house to ensure that products are made without any mistakes.

- The skills of workers must be developed to improve quality. We encourage workers to take national proficiency tests and have our own qualification system called Six Qualification System. This is a requirement for workers to work on production lines and workers are not allowed to get involved in making products unless they have passed the tests. Workers must take the tests once in every year. Workers who have passed the tests are not allowed to continue working permanently but must take the tests every year to develop and maintain their skills.

-

It is our principle that only one piece is made on a production line at a time. Only one piece is inspected, assembled, and checked on a production line at a time to make it easy to find mistakes and make quality more stable.

-

If a failure occurs, a sheet describing the cause for the failure is put on the wall of the workplace to attract attention to the failure to prevent it from occurring again.

-

We attempt to reduce the length of movement lines by, for example, reducing three workbenches to one. We eliminate unnecessary operations to reduce the burden on workers and increase the precision of work.

-

We ensure that the 5S activities are carried out; for example, all workers clean their workplaces together at a prescribed time every day. This makes it possible to detect all abnormalities early, resulting in stable quality.

-

We use paint markers to check tightening errors with a torque wrench. Products cannot be delivered without three marks of green, white, and yellow.

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어